Spotlights

Field Installer, HVAC Sheet Metal Installer, Sheet Metal Fabricator, Sheet Metal Installer, Sheet Metal Layout Mechanic, Sheet Metal Mechanic, Metal Fabricator

Sheet metal is a thin, flat material made from a wide range of metals, including aluminum, steel, tin, or pricier types such as copper, nickel, or even platinum. Usually rolled into coils or bought in flat pieces, sheet metal has an extensive range of industrial uses but requires trained Sheet Metal Workers to shape and install it. Although it's an often unsung career field, this profession has existed in some form since ancient times and continues to be a vital trade!

Specialized Sheet Metal Workers fabricate applicable metals into whatever precise design is needed for a particular job or product. Installation Sheet Metal Workers focus more on applying the metal securely, so it stays where it needs to be, whether it’s on a roof or around an air conditioning unit. There are also Maintenance Sheet Metal Workers who take care of cleaning and fixing up areas to ensure energy efficiency and Testing and Balancing Sheet Metal Specialists, who work with heating and cooling systems.

- Working in a time-honored profession involving skilled craftsmanship

- Learning to use a broad range of tools and metalworking techniques

- Ensuring buildings and systems are safe, secure, and energy-efficient

Working Schedule

- Sheet Metal Workers typically work full time and may have overtime or need to work after hours to respond to emergencies.

Typical Duties

- Reviewing blueprints and job specifications then choosing proper materials for the job

- Determining a proper sequence for assembly when needed

- Using tools and equipment in factory manufacturing environments

- Operating automated machinery

- Measuring, marking, cutting, bending, or drilling holes into metal sheets

- Trimming and smoothing material surfaces with power tools

- Shaping metal by using hand tools and anvils or blocks

- Fastening roofing down; working around solar panels

- Installing materials into frameworks, when applicable

- Creating computer-aided drafting and design layouts

- Basic programming to operate computerized equipment

- Installing HVAC ducts, signage, roofing, siding, or rain gutters

- Working with or around fiberglass or plastic sheeting

- Welding parts or using other methods to securely fasten them, such as bolting or riveting

Additional Responsibilities

- Hauling materials to job sites

- Training new workers on their duties

- Maintaining currency on any license or certification

- Discussing projects with clients, managers, and other workers

- Ensuring workplace safety and adherence to quality standards

- Conducting routine scheduled maintenance and inspections

- Making sure that HVAC systems are compliant with Leadership in Energy and Environmental Design specifications

Soft Skills

- Ability to work independently

- Attention to detail

- Commitment to safety

- Keen organizational skills

- Manual dexterity

- Normal vision and depth perception

- Hand and arm steadiness

- Physical stamina and strength

- Quick reaction time

- Skills for coordinating and instructing activities

- Sound judgment and decision-making, sometimes under pressure

- Time management

- Visualization

Technical Skills

- Ability to read blueprints and diagrams

- Familiarity with computer-aided design (CAD) software such as AutoCAD or PTC Creo Parametric

- Familiarity with computer-aided manufacturing (CAM) software such as Applied Production ProFab or JETCAM Expert

- Knowledge of general database query software and operating systems

- Math skills, including algebra and geometry

- Mechanical skills including use of construction materials and ability to use hand and power tools such as pliers, wrenches, grinders, hammers, cutters, caulking guns, chisels, deburring tools, drill presses, gas welding equipment, saws, hoists, levels, plasma arc welders, buffers, sanders, T-squares, tape measures, screwdrivers, and more

- Construction companies

- Governmental organizations

- Manufacturers

- Trade contractors and self-employment

Working with sheet metal is not an easy job! Depending on one’s specialty, they might work outdoors exposed to the elements or inside noisy factors doing repetitive work on their feet all day. Suffice it to say, either way, this role requires stamina, strength, and a good deal of flexibility, too. Metal isn’t easy to bend and shape, which is why it’s so crucial for buildings and why it’s so hard to work with. Sheet Metal Workers are expected to perform difficult, precision work involving materials made to resist manipulation!

There’s a high risk of injury due to the very nature of the work, plus the work environments themselves might pose hazards. For example, working on rooftops exposes one to the risk of falling from heights; working in a factory exposes you to dust, noise, and vibrations. Meanwhile, virtually any part of the job requires dealing with sharp metal pieces and tools that can easily cut you if you aren’t constantly vigilant. Those who perform welding duties face additional hazards such as burns from sparks. It’s crucial always to wear appropriate personal protective equipment and practice safe workplace habits to avoid mishaps!

A few of the factors impacting this sector include population growth and how well local economies are performing. New residential and commercial buildings will be needed in the coming years as populations continue to expand. However, in terms of existing structures and the current economy, it is cost-effective for local businesses to use Sheet Metal Workers just to fix up spots and maintain them so they’ll last longer.

Meanwhile, companies are increasingly opting to have energy-efficient HVAC systems in place. This is especially important for governmental buildings required to comply with specific standards, energy policies, or reform acts. Another influential factor is China’s aluminum industry, which affects global supply and prices.

Sheet Metal Workers were probably always very hands-on people who enjoyed creating and crafting things. They might have loved Play-Doh or other malleable substances or could have been intrigued by papercrafts or LEGOS, as well.

Independent and competent, they might have been content working alone on projects for long periods until everything was exactly the way they wanted it to come out! Chances are they were methodical, enjoyed following written or visual instructions, and following along with “how-to” videos. These are the types of traits most workers develop in their childhood and carry into their adult careers.

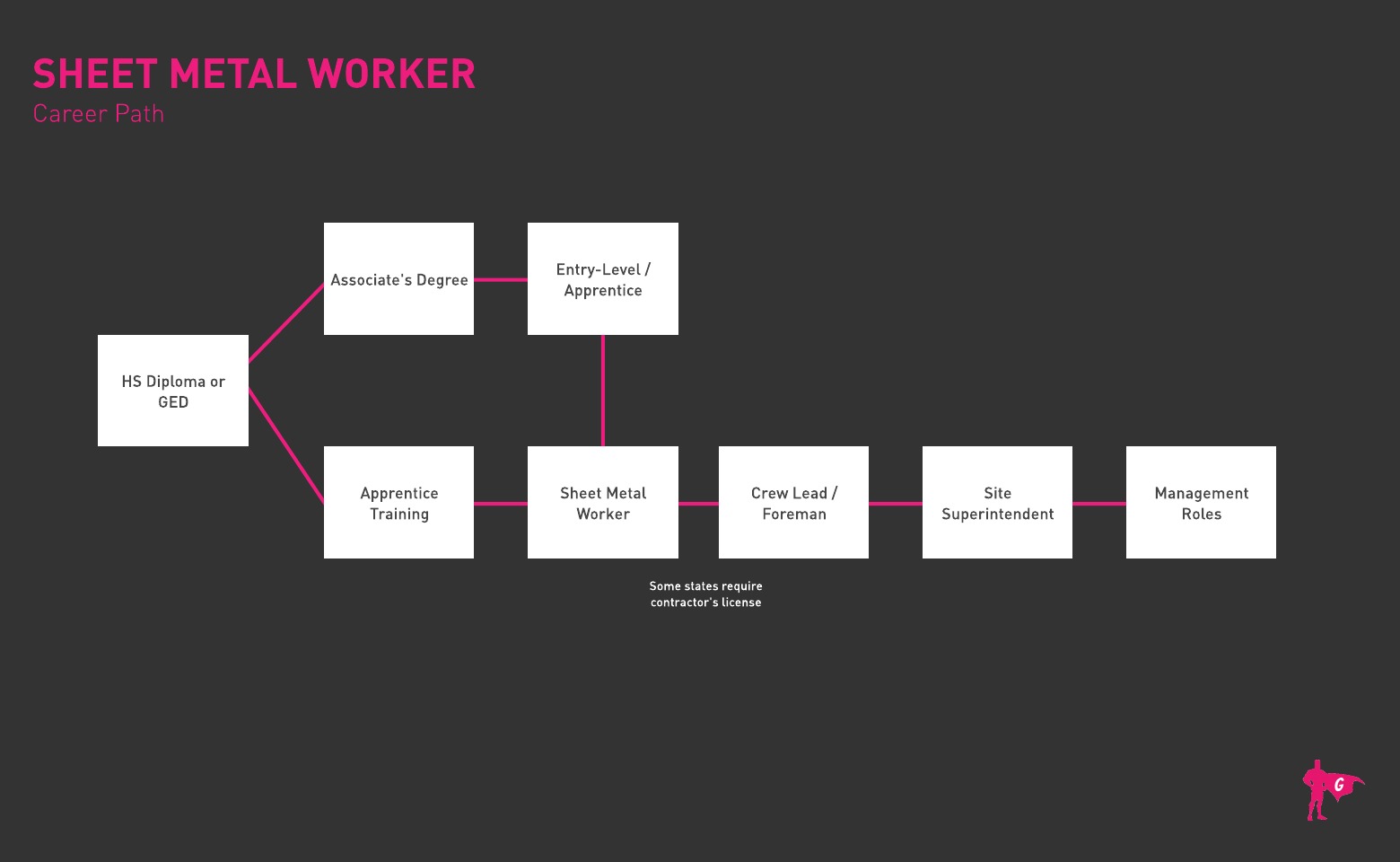

- Sheet Metal Workers usually only need a high school diploma to get started

- Many often take applicable courses at a community college or vocational training school

- Classes might include mechanical drawing, blueprint reading, building codes, welding, fabrication and other metalwork courses, first aid, and algebra or geometry

- Large employers might offer their own in-house training or outsource training to a local school that can prepare future employees to work at their factories

- Long apprenticeships are common and can last up to 4 or 5 years

- Before beginning an official apprenticeship, some people gain experience as helpers until they are 18 years of age or otherwise ready to start

- Unions or employers might sponsor apprenticeships. These will feature plenty of On-The-Job training supervised by an experienced Sheet Metal Worker

- After gaining competence, apprentices are considered journeymen

- Note, some states also require workers to have a contractor’s license

- Optional advanced certifications can help boost your competitiveness for jobs, such as:

- American Welding Society certifications

- International Certification Board - Certifications in Testing, Adjusting, and Balancing; or HVAC Fire Life Safety

- Fabricators & Manufacturers Association, International - Certification in Metal Fabrication

- A university degree isn’t required for Sheet Metal Work, but certain courses will help you be more competitive when looking for a job. Community college or vocational/technical schools are a great way to obtain some practical experience

- Most training will be done via apprenticeship, but if you do take classes in advance, try to get as much practical experience as you can

- If using federal aid Pell Grant funding, check to ensure the school or program is eligible

- Sign up for classes to learn mechanical drawing, CAD, CAM, blueprint reading, building codes, welding, fabrication, first aid, CPR, and applicable math

- If possible, knock out community college or vocational training while still in high school

- Search for apprenticeship opportunities on Indeed.com, Craigslist, or by reaching out directly to local companies

- Get some practical experience under your belt via part-time helper jobs that can expose you to work environments and teach you about applicable safety standards

- Check out online courses offered by the American Welding Society and Fabricators & Manufacturers Association, International

- Watch related YouTube tutorials and volunteer to assist with local projects such as ones undertaken by Habitat for Humanity

- Catch up on “how-to” articles from professional organization articles (see Recommended Websites below)

- U.S. News ranked Sheet Metal Worker as the #15 Highest Paying Job Without a Degree and #8 in Best Construction Jobs

- The outlook for Sheet Metal Workers is not particularly strong, currently tracking at a 1% growth over the next decade. To land a job, you’ll need to stand out from the crowd, either by education and training or from sufficient practical work experience

- Sign up for alerts on job boards like Indeed, SimplyHired, and ZipRecruiter, but also see if local companies are posting opportunities on Craigslist

- If you aren’t tied to a specific geographic location, check out BLS’s state and area data to learn where most Sheet Metal Worker jobs are

- Ask your college or vocational training center about their job-seeking resources. Many such schools serve as training pipelines for local employers

- You may or may not need a resume or cover letter, but just in case, check out some Sheet Metal Worker cover letter templates and Sheet Metal Worker resume samples

- Focus your application materials on relevant work and educational training

- Don’t be surprised if some employers peek at your social media (in other words, try to keep it clean and professional)

- Ask questions about promotion potential so you can get a clear picture of what’s expected and what you need to do to get ahead

- The more education and training you start your career with, the faster your apprenticeship might go. This can speed up your advancement to journeyman

- Obtain your contractor’s license if applicable, and knock out advanced professional certifications

- Be known for your dependability. Always be on time and ready to put your skill to use

- Be a problem solver! Find solutions by doing any necessary research on your own to demonstrate self-reliance

- Learn about manufacturer-specific best practices and don’t take shortcuts

- Show your commitment to workplace safety by wearing proper protective gear, following safety guidelines, staying current on first aid/CPR, and mentoring new workers

- Realize that small businesses might not have much room for growth, and sometimes you have to make your own opportunities as a self-employed entrepreneur

Websites

- American Welding Society

- Apprenticeships

- Fabricators & Manufacturers Association, International

- Helmet to Hardhats

- International Association of Sheet Metal, Air, Rail, and Transportation Workers (SMART)

- International Certification Board

- International Training Institute for the Sheet Metal and Air Conditioning Industry

- NCCER

- O*NET Sheet Metal Workers

- Sheet Metal and Air Conditioning Contractors’ National Association

Books

- Sheet Metal Workers' Manual: A Complete, Practical Instruction Book on the Sheet Metal Industry, Machinery and Tools, and Related Subjects, by Louis Broemel

- Sheet Metal Handbook: How to Form and Shape Sheet Metal for Competition, Custom and Restoration Use, Ron and Sue Fournier

- Professional Sheet Metal Fabrication, by Ed Barr

Sheet Metal Workers have hard, demanding jobs, and frankly, the long-term career outlook is not as stable as some other fields. BLS offers several closely-related occupations you might also want to consider, such as:

- Assemblers and Fabricators

- Boilermakers

- Glaziers

- Heating, Air Conditioning, and Refrigeration Mechanics and Installers

- Insulation Workers

- Machinists and Tool and Die Makers

- Metal and Plastic Machine Workers

- Roofers

- Solar Photovoltaic Installers

- Welders, Cutters, Solderers, and Brazers

Newsfeed

Programs at Foothill

Featured Jobs

Online Courses and Tools