Spotlights

Maintenance Technician, Industrial Mechanic, Maintenance Mechanic, Facilities Technician, Equipment Technician, Plant Maintenance Technician, Maintenance Engineer, Maintenance Electrician, Machine Repair Technician, Service Technician, Automated Manufacturing Technician

Roughly 75% of the goods we use are made with the help of industrial machines or processes. From electronics, appliances, and vehicles to furniture, clothing, and toys, we rely on things made by complex machines!

But these machines need constant maintenance to operate efficiently; otherwise, their parts can wear out quickly or they can simply break down. If one machine stops working, it can create a bottleneck that grinds the entire manufacturing process to a halt. When that happens, it’s very expensive for the company, which must pay workers to wait around while that machine gets fixed.

Such unplanned downtime can “cost a company as much as $260,000 an hour,” according to Aberdeen Research. So it’s no wonder why companies rely on Industrial Maintenance Technicians to ensure operations run smoothly.

The technicians inspect machines and equipment, perform preventative maintenance, and make minor repairs as needed to minimize downtown and maximize productivity. Their work can save companies millions of dollars a year!

- Ensuring smooth and efficient operation of industrial equipment

- Reducing downtime and increasing productivity

- Being a crucial part of the production process

- Helping companies maintain profitability so they can stay in business

Working Schedule

- Industrial Maintenance Technicians work full-time, including shifts that cover nights, weekends, and holidays. Overtime is sometimes required, especially during peak production periods or when urgent repairs are needed.

Typical Duties

- Perform routine inspections to ensure machinery is in good working order

- Use hand and power tools to conduct preventive maintenance aimed at preventing breakdowns

- Check equipment fluid levels, as necessary

- Clean, lubricate, and make minor adjustments to machinery, in accordance with manufacturer guidelines

- Use diagnostic equipment to troubleshoot mechanical, electrical, and hydraulic issues

- Repair or replace defective, damaged, or worn out parts.

- Maintain parts inventories

- Fabricate or grind parts to fit dimensions

- Perform basic wiring and welding as required

- Collaborate with other maintenance staff and production team members

- Assist in the installation of new equipment and machinery, following manufacturer specifications

- Calibrate and test equipment, if authorized to do so, to ensure optimal operation

- Provide training to junior technicians and machine operators

- Keep records of maintenance activities and issues on logs and work orders

- Ensure compliance with safety regulations and standards to avoid workplace injuries

- Mark equipment that is under repair or awaiting parts

- Tear down pieces that need to be moved or taken off-site

- Catalog parts carefully during disassembly

Additional Responsibilities

- Order supplies

- Prepare cost estimates

- Review technical manuals as needed

- Conduct tool and equipment inventory

- Ensure all testing tools are calibrated correctly prior to using them to test machines

- Prepare and use chemical cleaning products

- Practice all safety protocols to mitigate workplace mishaps

- Wear appropriate personal protective equipment, as needed

- Report machinery statuses and maintenance activities to supervisors

- Suggest improvements to enhance equipment performance and reliability

- Stay up-to-date on maintenance techniques, tools, and relevant software

Soft Skills

- Adaptability

- Analytical

- Attention to detail

- Coordination

- Evaluation skills

- Hand and finger dexterity

- Independent

- Observant

- Organization

- Patience

- Problem-solving

- Realistic

- Strength and stamina

- Strong reading skills

- Team player

- Time management

Technical Skills

Industrial Maintenance Technicians must be familiar with:

- Computerized maintenance management systems

- Diagnostic and precision tools

- Equipment maintenance, calibration, and repair

- Facilities management programs

- Industrial safety regulations

- Inventory management software

- Mechanical and electrical systems

- Programmable logic controllers

- Technical manual databases

- Technical manuals and blueprints

- Tools and equipment usage

- Welding and machining

- Automotive factories

- Commercial & industrial repair

- Construction

- Energy production facilities

- Food processing facilities

- Manufacturing plants

- Pharmaceutical plants

- Wholesale trade

The role of Industrial Maintenance Technicians involves physical labor, working in confined spaces, and being exposed to workplace hazards like noise, smoke, fumes, moving parts, and sharp metal.

Technicians have to stay vigilant to avoid mishaps. They’ve also got to be very knowledgeable about the machines and equipment they work on, so they can keep everything up and running as much as possible.

Since downtime due to breakdowns can be so costly, a lot is riding on the diligence of these workers. They simply can’t afford to lose track of maintenance schedules or to forget to perform some critical preventive fix. When something does go wrong, they’ve got to be ready to address it immediately – or know who to contact to do repairs beyond their scope of duty!

With advancements in technology, Industrial Maintenance Technicians are increasingly expected to work with sophisticated diagnostic tools and automated machinery.

Predictive maintenance, which uses data analytics to predict equipment failures before they occur, is getting more common every year. Technicians thus have to develop skills in data analysis and digital tools.

At the same time, the rise of automation and smart factories means that Industrial Maintenance Technicians need to be very familiar with programmable logic controllers and other automated systems. This shift is creating new opportunities for those who can combine traditional mechanical skills with knowledge of advanced technology.

Many Industrial Maintenance Technicians enjoyed tinkering with mechanical devices, fixing bikes, or disassembling gadgets to see how they work. They often had a natural curiosity about how things function, as well as a general knack for problem-solving. High school shop classes, science fairs, and hands-on projects likely played a significant role in their early interest in this career field!

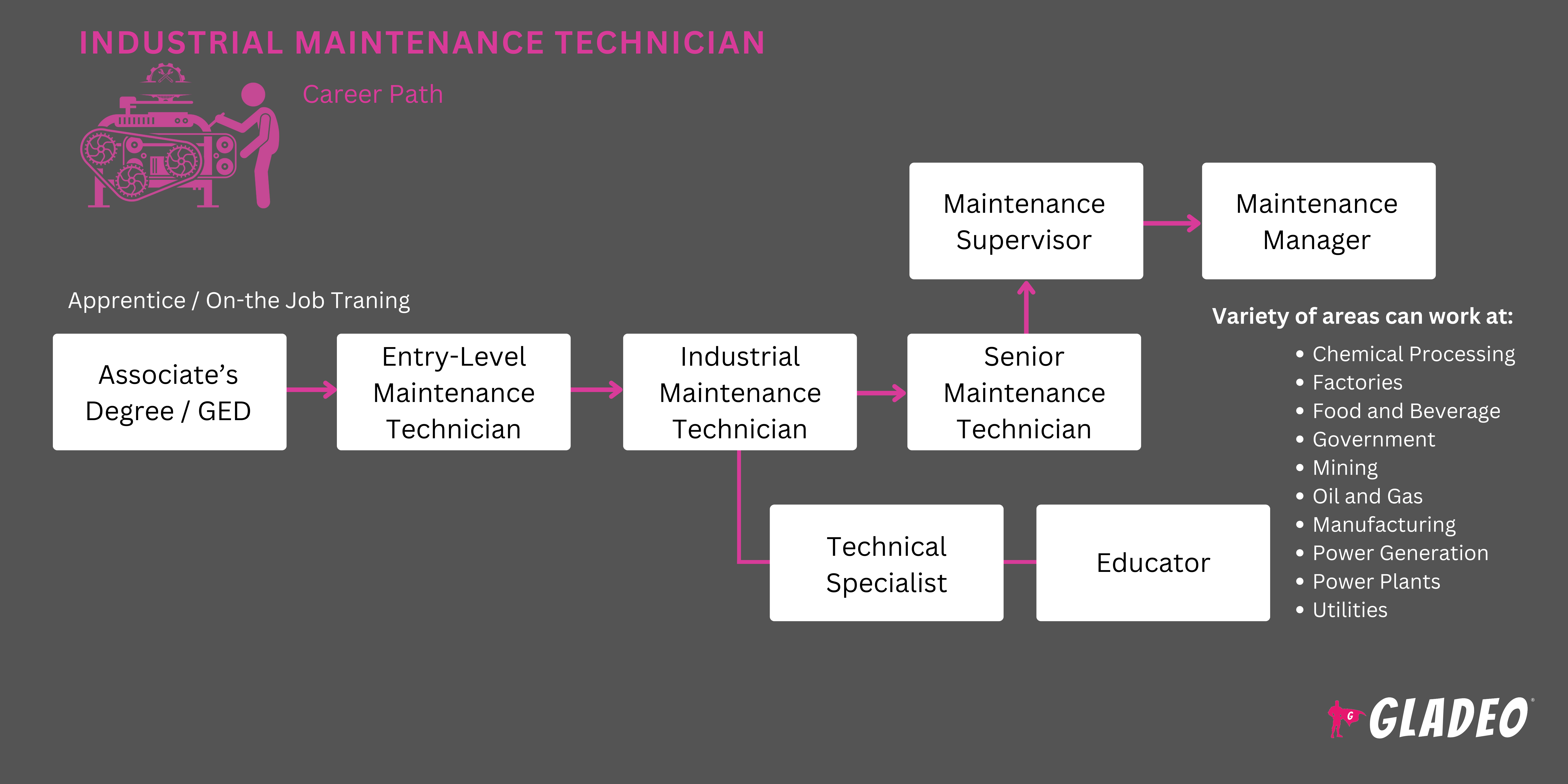

- Industrial Maintenance Technicians need a high school diploma or equivalent. A college degree isn’t required

- Many technicians get started through apprenticeship programs. Some can get hired if they have sufficient relevant experience, and then they just receive On-the-Job training for job-specific tasks

- Community colleges and technical schools offer certificates or associate degrees in industrial maintenance, mechatronics, and related fields. These can make applicants more competitive and help them qualify for more job opportunities

- Relevant educational coursework includes topics such:

1. Automation and Control Systems

2. Blueprint Reading

3. Computer-Aided Design

4. Electrical Systems

5. Energy Management Systems

6. HVAC Systems

7. Hydraulics and Pneumatics

8. Industrial Electronics and Robotics

9. Instrumentation and Measurement

10. Machine Tool Technology

11. Material Science And Metallurgy

12. Mechanical Systems

13. Preventive Maintenance Strategies

14. Process Control Systems

15. Programmable Logic Controllers

16. Welding

- Some employers require applicants to be certified through organizations like the Society for Maintenance & Reliability Professionals’ Certified Maintenance and Reliability Technician (CMRT)

- The CMRT exam contains 175 multiple-choice questions and can be taken at over 5,500 testing centers

- “The CMRT exam tests competency and knowledge of specific tasks within four domains: Maintenance Practices, Preventative and Predictive Maintenance, Troubleshooting and Analysis, and Corrective Maintenance,” per SMRP

- As of 2024, the exam fee cost for SMRP members is $300; for non-members, it’s $470

- Other popular certifications include:

- International Council for Machinery Lubrication - Machine Lubricant Analyst or Technician

- International Fluid Power Society - Fluid Power Mobile Hydraulic Technician

- Packaging Machinery Manufacturing Institute - Mechatronics: Fluid Power 1

- Occupational Safety and Health Administration (OSHA) - Hand and Power Tools and general industry courses

- Due to the importance of the role, technicians might also need to pass a background check and have a valid driver’s license, so they can respond to an after-hours emergency

- A four-year degree is not needed, but students can take preparatory college classes at a community college or vocational school.

- Look for accredited programs with plenty of hands-on training components, as well as internships or cooperative education experiences.

- Compare tuition and fees costs, noting in-state vs. out-of-state costs.

- Review scholarship and financial aid options.

- Check out job placement statistics for students who complete the programs.

- If applying for federal aid Pell Grants, make sure the money can be used to pay the tuition at your particular school of interest.

- Veterans can look for military-friendly schools that have VA benefit experts to help navigate the system.

- Take applicable classes to learn about simple programming, welding, safe use of hand tools, hydraulics and pneumatics, reading blueprints, doing shop math, and working on electronics

- Get all the practical experience as you can at school and through part-time jobs or apprenticeships

- Talk with technicians to learn about their day-to-day work activities

- Watch YouTube videos and read articles about industrial maintenance

- Consider extracurricular activities like robotics clubs

- Pursue a relevant technical training program after finishing high school

- Build a network of industry contacts and keep in touch with them

- Review job ads on sites like ZipRecruiter, SimplyHired, Indeed, Monster, and Glassdoor

- Read the required and preferred skills listed in the job ads

- Pay attention to the keywords used in job ads, and use them in your resume. Keywords might include:

- Blueprint Reading

- CMMS (Computerized Maintenance Management Systems)

- Diagnostics

- Electrical Systems

- Equipment Installation

- HVAC Systems

- Hydraulics

- Inventory Management

- Lean Manufacturing

- Machine Calibration

- Mechanical Repair

- OSHA Compliance

- PLC Programming (Programmable Logic Controllers)

- Pneumatics

- Predictive Maintenance

- Preventive Maintenance

- Root Cause Analysis

- Safety Protocols

- Welding and Fabrication

- If applying for an apprenticeship, list any related work experience or skills on your application

- Consider doing OSHA certifications for hand tools or general industry

- Ask people in your network to let you know if they hear about job openings

- Attend job fairs and industry events to connect with potential employers

- Ask previous supervisors or teachers to write recommendation letters or request their consent (in advance) to list them as references

- During interviews, demonstrate a keen awareness of trends in the industry

- Review resume templates for Industrial Maintenance Technician and check out sample interview questions

- Run through some mock interviews with friends or your school’s career center

- Dress professionally for job interviews

- Let your supervisor know you’re interested in growth opportunities when the time is right. Focus first on the job you were hired for and share your willingness to learn and advance

- Master your duties then keep learning more! Take advanced courses or complete specialized certifications

- Ask equipment and machine manufacturers about trends and new developments you should become familiar with. Chances are they’re happy to talk shop with you!

- Use downtime to study technical manuals

- Be proactive. Look up answers for yourself but ask questions if something is unclear or you need a hands-on demonstration. Seek out mentorship but prove you can do the work on your own, without assistance

- Train others properly, because if they make mistakes, it reflects back onto the training you gave them

- Stress safety and compliance at all times. Be a workplace leader and set an example!

- Earn a reputation as someone who is reliable and gets the job done right

- Join professional organizations such as the Society for Maintenance & Reliability Professionals to grow your network and discover new opportunities

- Stay current on regulatory changes to ensure your organization is always compliant

Websites

- Associated General Contractors of America

- International Association of Machinists and Aerospace Workers

- International Brotherhood of Electrical Workers

- International Council for Machinery Lubrication

- International Fluid Power Society

- International Society of Automation

- Industrial Supply Association

- National Association of Manufacturers

- National Institute for Certification in Engineering Technologies

- National Tooling and Machining Association

- Occupational Safety and Health Administration

- Packaging Machinery Manufacturing Institute

- Precision Machined Products Association

- Society for Maintenance & Reliability Professionals

- United Brotherhood of Carpenters and Joiners of America

- United Steelworkers

Books

- Industrial Maintenance, by Michael E. Brumbach and Jeffrey A. Clade

- Industrial Mechanics and Maintenance, by Larry Chastain

- Machinery’s Handbook Toolbox, by Erik Oberg

- Maintenance Fundamentals, by R. Keith Mobley

- Reliability-Centered Maintenance, by John Moubray

Industrial Maintenance Technicians are key players in any manufacturing facility. But if you’re curious about other occupations that require similar skills, check out our list below!

- Automotive Service Technician and Mechanic

- Boiler Operator

- Control and Valve Installer

- Electrical and Electronics Engineer

- Electrician

- Electric Motor Repairer

- Facility Maintenance Manager

- HVAC Technician

- Industrial Engineering Technologist

- Industrial Machinery Mechanic

- Machine Feeder

- Machinist

- Mechanical Engineer

- Medical Equipment Repairer

- Mobile Heavy Equipment Mechanic

- Plumber, Pipefitter, and Steamfitter

- Production Supervisor

- Rail Car Repairer

- Tool Grinder

- Welder

- Wind Turbine Technician

- Woodworking Machine Setter

Newsfeed

Featured Jobs

Online Courses and Tools