Spotlights

Boiler Maker, Boiler Mechanic, Boiler Repairman, Boiler Service Technician, Boiler Technician, Boilermaker, Boilermaker Mechanic, Boilermaker Pipe Fitter, Boilermaker Welder, Service Technician

Boilers are large, heavy metal vessels used for heating fluid then distributing the vaporized fluid for water or building heating, cooking, or other purposes. Boilermakers are in charge of assembling and installing boilers correctly then performing routine inspections, maintenance, and repairs, when needed.

They rely on a variety of methods including welding and riveting, and might need to call in help from a crane to move particularly heavy parts. Boilermakers must be experts with several hand and power tools, many of which are dangerous and require special training to use. In addition, they can fix other equipment such as smokestacks, storage tanks, blast furnaces, and even water treatment plants. They might even get tagged to work on dam pipes or do some brickwork.

- Ensuring hazardous boilers are properly maintained to keep buildings warm

- Learning specialized mobile trade skills that can be put to use anywhere

- Helping businesses and commercial property stay productive

Working Schedule

- Boilermakers usually work full-time, including overtime if a boiler isn’t working right and needs to get back up and running fast. However, contracted work can be intermittent with sporadic downtimes.

Typical Duties

- Review blueprints and assess the best spot to install a boiler

- Lay out parts and determine any metal bending or cutting requirements

- Carefully assemble tanks using welding or bolting equipment

- Put in prefabricated boilers following manufacturer’s guidelines

- Ensure boilers are working within specifications; perform tests and check for problems

- Keep boilers clean using chemicals and brushes

- Perform routine or as-needed maintenance, and test for leaks

- Fix or swap out any defective parts, using applicable hand or power tools

- Insert bricks or suitable heat-resistant material in fireboxes

- Replace valves, pipes, and joints, if necessary

Additional Responsibilities

- Follow proper maintenance schedules; annotate work logs, if required

- Refer to applicable technical manuals to ensure proper assembly and installation

- Conduct tool and equipment inventories

- Calibrate any necessary testing equipment

- Practice safety protocols and wear personal protective equipment to avoid injuries and mishaps

Soft Skills

- Analytical

- Attention to detail and standards

- Comfortable in confined spaces

- Coordination

- Critical thinking

- Evaluation and problem-solving skills

- Fast reaction time

- Hand and finger dexterity

- Normal vision

- Observant

- Realistic

- Sound judgement

- Strength (including core and static)

- Teamwork

- Time management

Technical Skills

- Blueprint reading

- Computer aided design

- Cutting

- Drafting skills

- Enterprise resource planning

- Hand signals

- Knots

- Knowledge of mechanical equipment

- Layout and fabrication

- Rigging

- Tube rolling

- Welding

- Familiarity with tools and equipment such as wrenches, air compressors, manifolds, samplers, hammers, bench vises, bevels, blow torches, bolt cutters, C clamps, calipers, chisels, compasses, drill gauges, drive pins, electrode holders, pliers, fire extinguishers, forklifts, gas welding, girder trolleys, hacksaws, hex keys, hoists, jacks, ladders, lasers, level sensors, mill saw files, milling machines, nibblers, multi gas monitors, pipe cutters, plasma arc welding machines, platform lifts, power buffers, pressure indicators, pry bars, punches, putty knives, resin guns, scribers, shackles, shears, slings, socket sets, tape measures, and many more

- Metal product manufacturing

- Building construction

- Plumbing, heating, and air-conditioning service providers

- Utility system construction

Boilers are built to last, but always require maintenance and repair services from highly-trained workers. Boilermakers are expected to be masters of their craft, able to come in and get the job done right, whether it's putting in new boilers or taking care of older ones. Boilers operate under intense pressure and can be dangerous if not properly assembled and managed. Some have been in operation for decades, requiring extra attention to ensure they’re still safe to run.

Because of the plethora of hand and power tools used to perform boiler work, Boilermakers must expect, and take precautions against, multiple workplace hazards. Attention to detail is crucial at all times, and proper personal protective equipment (PPE) should always be worn to help mitigate injury. All assembly, maintenance, and repair procedures should be correctly followed and safety standards complied with, because Boilermakers have to protect themselves, their co-workers, and naturally anyone working inside a building or area where a boiler is running.

Boilers can cost thousands of dollars, so sometimes a business will opt to repair versus replace an older one, depending on their own financial situation. A turbulent economy can impact these decisions, leading to less new boilers being purchased, and thus less work for Boilermakers. There’s always a need for maintenance and repair, but that doesn’t always add up to full-time work, especially for contractors.

Global Market Insights remains optimistic that “rising industrialization along with surging investments toward the expansion of existing manufacturing facilities will create significant market opportunities for...boiler manufacturers.” They also cited trends in refinery expansion, non-condensing heating tech, and growing demand for processed foods, all of which should positively impact the sector and spur job creation!

Boilermakers aren’t afraid to get their hands dirty! They likely always enjoyed working on projects, putting things together piece-by-piece then testing them to make sure they worked. They’re builders and tinkerers who are safety-conscious and take the time to perform tasks correctly. They might have been given responsibilities early on as children, or may’ve had limited resources to work with, making them eager to take precious care of what they’d been given. People in this field can be extroverted, so while they’re at ease working alone they’re also great with teams. They tend to have a very practical streak and solid work ethic, traits they could have developed when growing up.

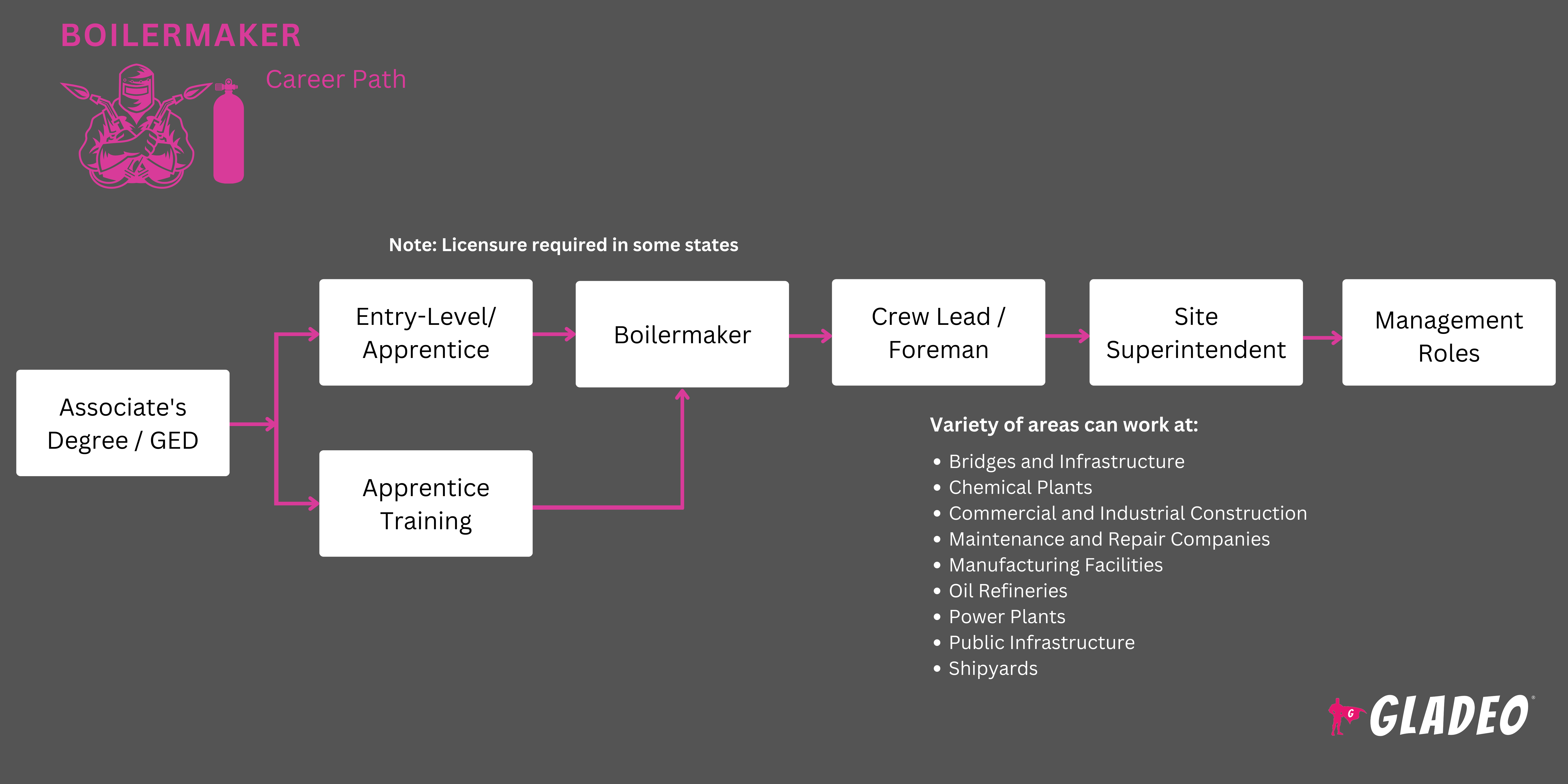

- Most Boilermakers earn their high school diploma or GED then begin an apprenticeship

- Apprenticeships last ~4 years, after which the worker achieves journey level

- Programs may be sponsored by unions and contractor associations, such as the Boilermakers National Apprenticeship Program which gives preference “on the basis of welding qualifications, and then on the basis of random selection, as set forth in the approved standards and selection procedures of the National Joint Apprenticeship Committee for the trade”

- Training covers tool and equipment usage, metals, installation, blueprints, and safety

- Licensure is required in some states

- National Center for Construction Education and Research (NCCER) Boilermaker certification is needed for some positions, as is Welding certification

- Honorably discharge Veterans can apply to Helmets to Hardhats

- Boilermakers might take some college courses, but won’t need to attend a full four-year university. Community colleges/vocational training programs offer more affordable tuition

- Most (if not all) training will be done via apprenticeship, such as the Boilermakers National Apprenticeship Program

- Those who attend college should look for activities to put skills into practice

- If using federal aid Pell Grant funding, check to ensure the school or program is eligible

- Take classes that can help you gain hands-on experience with tools and applicable equipment usage, metal work, blueprint reading, welding, safety, and first aid

- Try to gain some work experience via part-time jobs that give you skills practice

- Keep a log of the tools and equipment you learn how to use

- Scout for apprenticeships (like the Boilermakers National Apprenticeship Program) or training like NCCER’s Boilermaker certification

- Meet working Boilermakers to ask questions; see if they’ll let you shadow them at work

- Watch videos that show exactly what the work entails so you know what to expect

- Getting an apprenticeship isn’t a given; you have to apply and be competitive!

- Those with welding, pipefitting, millwright work, and sheet metal work experience will have an edge; they might even get some time shaved off their apprenticeship

- For your job or apprenticeship applications, be honest about your background, use correct terminology, and list any completed extracurricular activities that demonstrate potential

- If a resume is needed, be sure to list all finished education and training, work history, and skills acquired

- Ask a friend or editor to review your application for mistakes or ways to enhance it

- Let everyone in your network know when you’ve started your job search

- ZipRecruiter, SimplyHired, Indeed, Monster, and Glassdoor are good places to see what’s out there, but you can also check out Craigslist, Apprenticeship.gov, and Boilermakers.org

- Do your best in all training, including apprenticeships. They’re long, but stay motivated and always be positive throughout the entire course of work and study

- Master every skill you’re taught, and every tool you’re shown, then ask to learn more

- Constantly expand your knowledge base, and try to get experience on as many types of boilers and related equipment as you can

- Eliminate any gap areas through practice and self-study

- Ask your boss for suggestions about college courses, advanced training, or certifications

- Talk to manufacturers about new developments you should learn about

- Don’t wait for someone to tell you to study technical manuals

- Ask questions but when possible, look things up and show initiative and preparedness

- If the job allows, train others when you’re ready...and do a great job passing on everything you’ve learned. Treat new workers how you want to be treated

- Stay in compliance with safety standards at all times, including wearing your protective gear (even when you don’t “want” to)

- Be a team player, an attentive follower, and a strong leader. Earn a rep as someone who is competent and knows what they’re doing!

Websites

- American Welding Society

- Boilermakers National Apprenticeship Program

- Helmet to Hardhats

- International Brotherhood of Boilermakers, Iron Ship Builders, Blacksmiths, Forgers and Helpers

- National Association of Construction Boilermaker Employees

- National Center for Construction Education and Research (NCCER)

Books

Job growth for Boilermakers isn’t expected to be stellar over the coming decade, but things change. If you’re looking for something with a bit more certainty or you simply want to explore other options, check out related occupations listed by the Bureau of Labor Statistics’ Occupational Handbook and O*Net Online:

- Assemblers and Fabricators

- Industrial Machinery Mechanics, Machinery Maintenance Workers, and Millwrights

- Insulation Workers

- Ironworkers

- Machinists and Tool and Die Makers

- Maintenance and Repair Workers

- Plumbers, Pipefitters, and Steamfitters

- Sheet Metal Workers

- Stationary Engineers and Boiler Operators

- Telecommunications Line Installers and Repairers

- Welders, Cutters, Solderers, and Brazers

Newsfeed

Featured Jobs

Online Courses and Tools